Composites technology

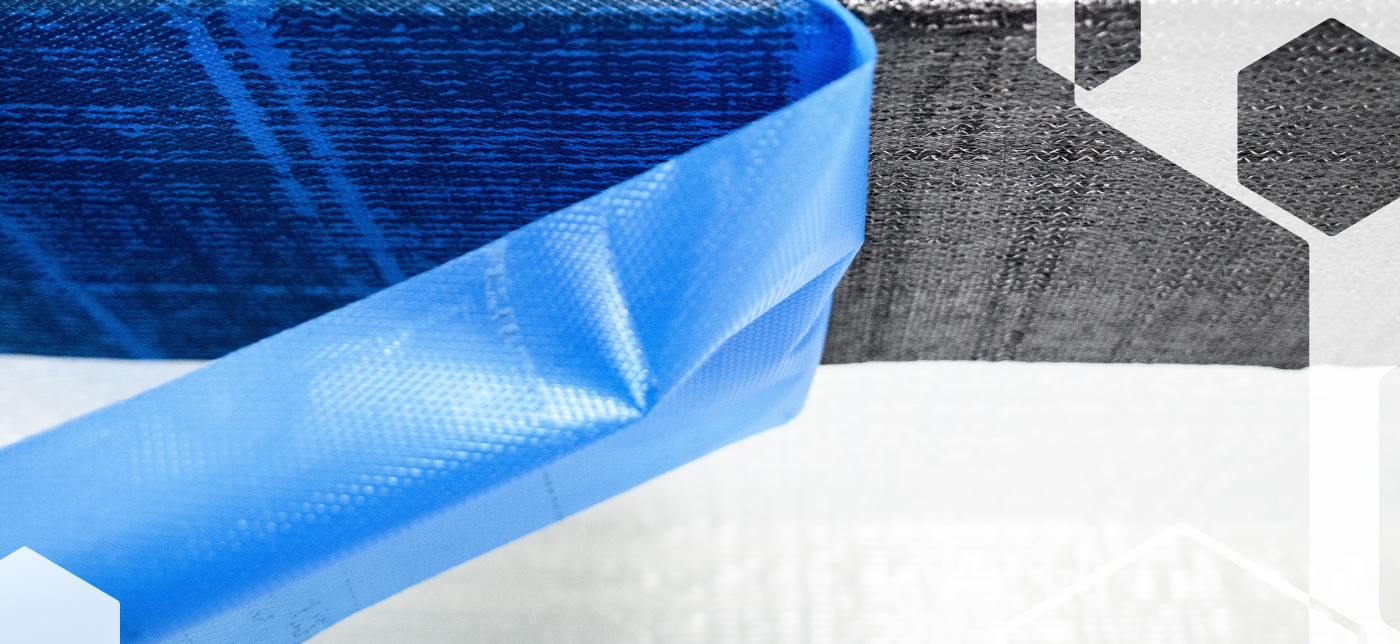

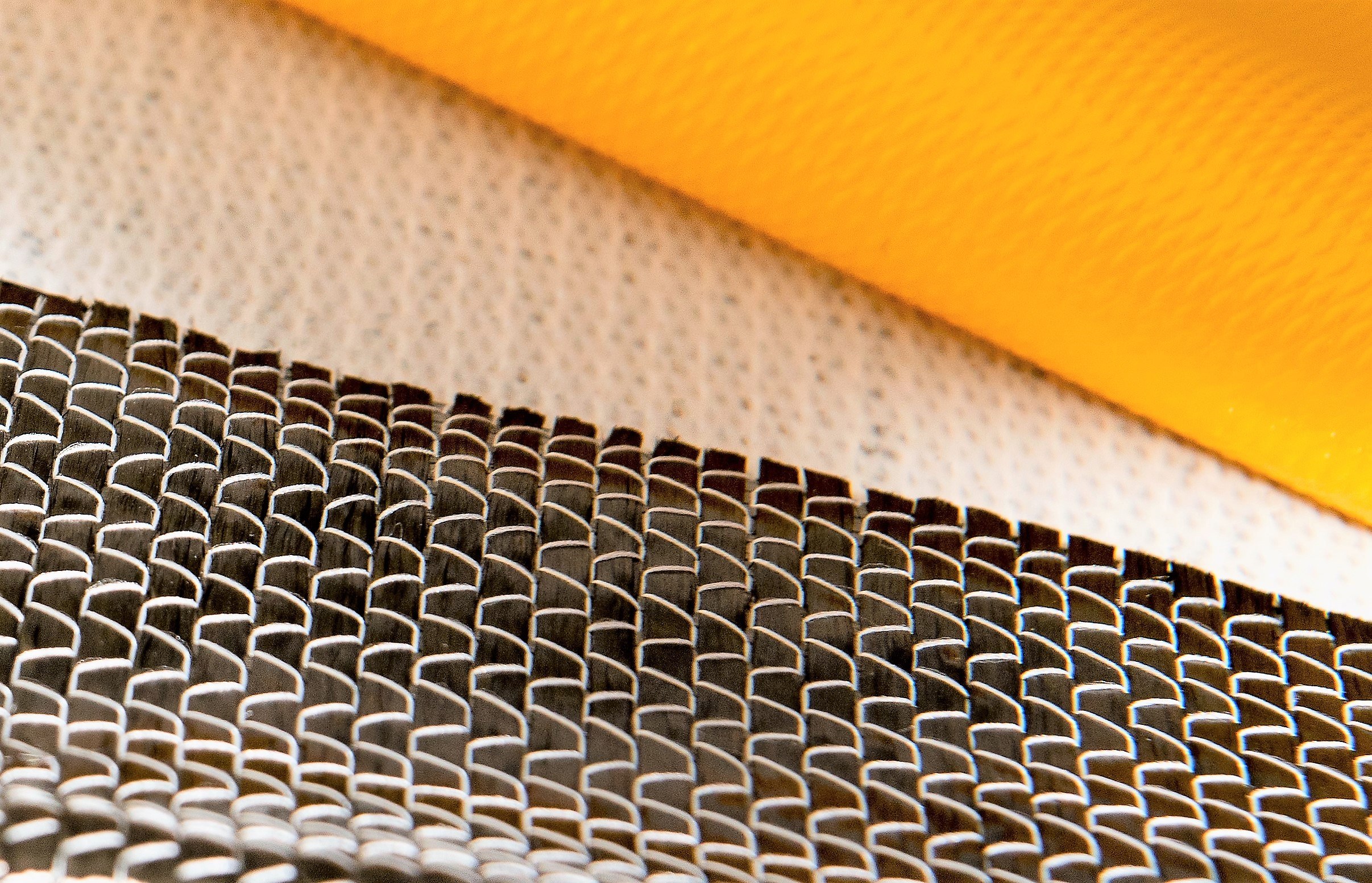

Prepregs

Prepreg materials enable the ultimate in high performance composite solutions when lightness and strength are the key requirements.

Catalyzed resin systems are combined with reinforcement fabrics – this impregnation stage takes place in the factory before the materials are used, hence the name “prepreg or pre-impregnated” – then the prepregs are chilled and stored in freezers to stop the reaction of the resin system matrix. When required in production, the prepreg materials are defrosted and cut to size before being laid up in the mould, consolidated under vacuum, and cured in an oven or autoclave.

Prepregs deliver the optimum fire, smoke and toxicity performance for composite components as well as reducing waste and improving the consistency of finished parts through precise control of the resin content in the laminate.